WafPak System

WafPak System

WafPak System

WafPak System

Introduction

In the world of semiconductor manufacturing and electronic component handling, the safety and integrity of silicon wafers are paramount. The WafPak Silicon Wafer Protection System has been meticulously designed to meet the rigorous demands of these industries, providing a comprehensive packaging solution that combines security, convenience, and reliability. This system is more than just packaging—it’s a vital part of ensuring that your wafers reach their destination in perfect condition, free from contamination, damage, and electrostatic discharge (ESD).

What is the WafPak Silicon Wafer Protection System?

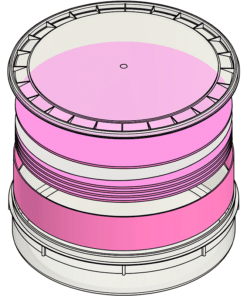

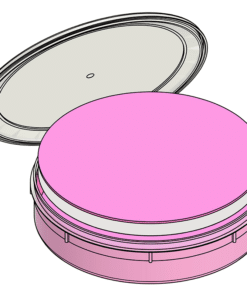

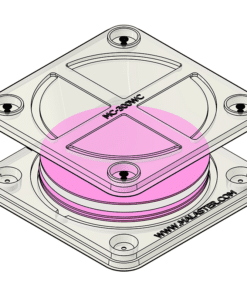

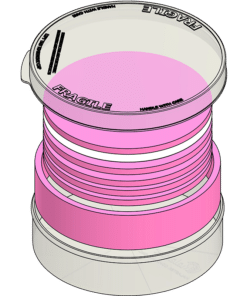

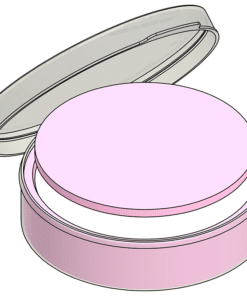

The WafPak Silicon Wafer Protection System is an all-inclusive packaging solution that has been engineered to protect silicon wafers during storage, handling, and transportation. Unlike traditional methods where each component is sourced and assembled separately, the WafPak System comes pre-assembled and ready to use. It includes a precision-engineered jar, custom-fit foam cushions, and wafer interleaf separators, all designed to work together seamlessly to provide unmatched protection for your silicon wafers.

Key Features of the WafPak System

1. Comprehensive ESD Protection

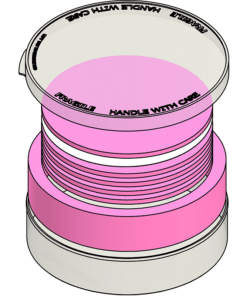

One of the most significant threats to silicon wafers is electrostatic discharge (ESD), which can cause irreparable damage to the delicate structures within the wafers. The WafPak System is specifically designed to mitigate this risk by incorporating ESD-safe materials and construction techniques. The jars are made from conductive or dissipative materials, which work in tandem with the foam cushions and interleaf separators to create a controlled environment that dissipates static charges safely.

- ESD Safe Materials: The conductive jars and dissipative foam work together to neutralize any potential electrostatic discharge, ensuring that your wafers are protected from the moment they are placed inside the system.

- Wafer Interleaf Separators: These separators are crucial for preventing wafers from coming into direct contact with each other, which could lead to damage from friction or static buildup. The separators maintain a safe distance between each wafer, allowing for secure stacking and easy access.

2. Custom-Fit Foam Cushions

The WafPak System includes custom-cut foam cushions that are tailored to the exact dimensions of your silicon wafers. This customization ensures a snug fit, preventing any movement or shifting during transport. The foam cushions not only provide physical protection against shocks and vibrations but also contribute to the overall ESD protection by dissipating any static charges that may accumulate.

- Shock Absorption: The foam cushions are designed to absorb shocks and vibrations, which are common during transportation. This absorption minimizes the risk of mechanical damage to the wafers.

- Precision Fit: The custom-fit design ensures that each wafer is securely held in place, eliminating the risk of movement that could lead to chipping, cracking, or scratching.

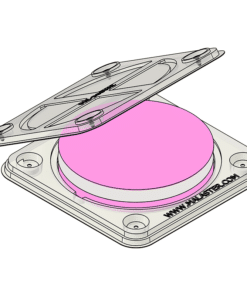

3. Ready-to-Use Packaging

The WafPak System is delivered to you fully assembled and ready for immediate use. This pre-assembly saves you time and effort, as there is no need to source individual components or worry about assembling them correctly. Simply place your silicon wafers into the system, close the lid, and your wafers are protected and ready for storage or transport.

- Time-Saving Solution: With the WafPak System, there’s no need for manual assembly, reducing the time and labor costs associated with packaging.

- Ease of Use: The pre-assembled nature of the WafPak System makes it incredibly user-friendly. Whether you’re packaging wafers for storage or shipping them to a client, the process is quick and straightforward.

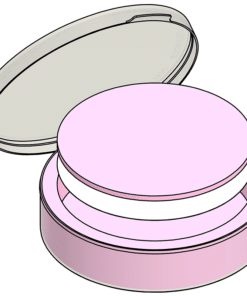

4. Durability and Reusability

The WafPak System is built to last. The materials used in the construction of the jars, foam, and separators are all selected for their durability and longevity. This means that the WafPak System can be reused multiple times, offering long-term value and reducing the overall cost of packaging.

- Long-Term Durability: The robust construction of the WafPak System ensures that it can withstand repeated use without compromising on protection.

- Cost-Effective: By using a reusable system, you reduce the need for constant repurchasing of packaging materials, leading to significant cost savings over time.

5. Customization Options

Understanding that different customers have different needs, the WafPak System is available with various customization options. Whether you need specific jar sizes, foam densities, or interleaf materials, we can tailor the WafPak System to meet your exact specifications.

- Custom Sizes: The WafPak System can be manufactured to accommodate wafers of various sizes, ensuring a perfect fit for your specific requirements.

- Material Choices: Depending on your needs, we offer a range of materials for both the jars and the foam cushions, allowing you to choose the best combination for your application.

Applications of the WafPak Silicon Wafer Protection System

The WafPak System is versatile and can be used across a wide range of industries that require the highest level of protection for silicon wafers. Some of the key applications include:

- Semiconductor Manufacturing: The WafPak System is ideal for use in semiconductor fabs, where wafers need to be protected during various stages of production, from initial fabrication to final assembly.

- Research and Development: For research labs that handle prototype wafers or small production runs, the WafPak System offers the perfect balance of protection and convenience.

- Supply Chain Logistics: Whether you are shipping wafers across the country or around the world, the WafPak System ensures that your wafers arrive at their destination in pristine condition.

Customer Testimonials

Our customers have experienced firsthand the benefits of using the WafPak Silicon Wafer Protection System. Here’s what some of them have to say:

- “The WafPak System has revolutionized how we package and transport our wafers. The ESD protection is top-notch, and the pre-assembled nature of the system saves us so much time.”

- “We’ve been using the WafPak System for several months now, and it’s been fantastic. The custom-fit foam ensures our wafers are always secure, and we haven’t had any issues with damage during shipping.”

Conclusion

The WafPak Silicon Wafer Protection System is the ultimate solution for anyone who needs to protect silicon wafers from the dangers of ESD, contamination, and physical damage. With its comprehensive protection, ease of use, and customization options, the WafPak System is the best choice for ensuring the safety and integrity of your wafers.

Whether you’re a semiconductor manufacturer, a research lab, or a logistics provider, the WafPak System offers the protection and convenience you need. Don’t leave your wafers at risk—invest in the WafPak Silicon Wafer Protection System today and experience the peace of mind that comes with knowing your wafers are protected by the best in the industry.