CleanTech Separators

CleanTech Separators

CleanTech Separators

CleanTech Separators

Malaster’s CleanTech Separators are designed for industries requiring the highest standards in electrostatic discharge (ESD) protection, contamination control, and mechanical safeguarding. These separators are primarily used in the semiconductor and electronics sectors, providing essential protection for delicate components like silicon wafers and electronic dies. However, their versatility extends to other industries, including solar energy, aerospace, and defense, where contamination prevention and surface protection are equally critical.

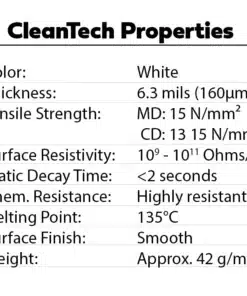

Detailed Product Specifications

CleanTech Separators are made from Tyvek®, a nonwoven material known for its exceptional strength, durability, and lightweight properties. Tyvek’s unique structure provides the perfect combination of cleanliness and protection, making it suitable for sensitive high-tech applications.

- Material: Tyvek® (High-Density Polyethylene)

- Material Type: Nonwoven, highly durable, and lightweight

- Surface Texture: Features both smooth and rough sides to offer flexibility in application, from contamination control to sensitive component protection.

- Thickness: 6.3 mils, offering the optimal balance of strength and flexibility.

- Weight: 1.60 oz/yd², making it lightweight and easy to handle in high-precision environments.

- Tensile Strength:

- Machine Direction (MD): 24.2 lbƒ/in

- Cross Direction (CD): 27.9 lbƒ/in

- Tear Strength:

- Elmendorf Tear (MD): 1.3 lb

- Elmendorf Tear (CD): 1.2 lb

- Delamination Strength: 0.25 lbƒ/in, ensuring the material remains intact and robust, even during extended use.

- Surface Resistivity: Ranges from 107 to 1011 ohms/square, providing effective electrostatic discharge protection in ESD-sensitive environments.

- Static Decay: Less than 2 seconds, ensuring rapid dissipation of any static charge during handling.

These separators are specifically designed to handle high-performance requirements in industries such as semiconductors, electronics, and aerospace, offering superior protection against contamination, static discharge, and physical damage.

Why Use Malaster Products?

Malaster’s CleanTech Separators offer a unique blend of protection, cleanliness, and ESD control. Here’s why you should choose Malaster’s solutions over others:

- Expertise in ESD Control: Protect your sensitive components, such as silicon wafers, from static electricity that can cause irreversible damage.

- FOD Prevention: CleanTech Separators help prevent Foreign Object Debris (FOD) in environments where even the smallest particles can cause significant damage.

- Trusted Across Industries: Whether you’re working in semiconductor, electronics, or aerospace, CleanTech Separators provide superior protection and performance.

With over two decades of experience in supplying high-performance materials, Malaster has developed the CleanTech line to address specific industry challenges, providing a product that delivers real-world results.

Technical Specifications

- Antistatic Coating: Applied to suppress static generation during handling.

- Corona Treatment: Enhances surface adhesion for printing or applying additional coatings.

- Low Particulate Shedding: Tyvek 1056DR is known for its nonwoven, continuous fiber structure, which minimizes shedding and protects delicate surfaces.

- Recyclable: Tyvek® is recyclable in typical HDPE recycling streams, making it an environmentally conscious choice.

Compliance Information (Industry Compliance and Quality Assurance)

CleanTech Separators meet or exceed various industry standards, including:

- RoHS Compliance: Ensures that no hazardous substances are present, making it suitable for electronic applications.

- REACH Compliance: Free from substances of very high concern (SVHC), CleanTech Separators align with European chemical regulations, ensuring safety in all applications.

- Antistatic Performance: Tested per EIA STD 541, CleanTech Separators provide fast static dissipation, ensuring that static buildup does not cause contamination or damage to sensitive electronic components.

Practical Applications

CleanTech Separators are ideal for industries requiring both surface protection and ESD control:

- Semiconductor Industry:

- Wafer Separators: Protect silicon wafers at every stage of production, from raw wafer to diced dies.

- Die Trays: Used to separate and protect individual dies during manufacturing and packaging.

- Electronics:

- ESD Protection: Shield circuit boards, chips, and other electronic components from electrostatic discharge.

- Packaging: Used to protect fragile components from scratches, marking, and contamination during shipping and storage.

- Aerospace and Defense:

- Contamination Control: Protect critical components and sensitive materials from FOD during manufacturing and transport.

- Cleanroom Compatibility: Ideal for use in cleanroom environments where particulate contamination could compromise product integrity.

- Solar Industry:

- Solar Cell Separation: CleanTech Separators are used to protect delicate solar cells during the production and shipping stages, reducing the risk of damage and contamination.

Key Benefits

- Electrostatic Discharge Protection: CleanTech Separators are treated with an antistatic coating, ensuring rapid static dissipation and eliminating the risk of static buildup during handling.

- Low Contamination Risk: The smooth, durable surface minimizes particulate shedding, making CleanTech Separators ideal for cleanroom environments and FOD protection.

- Chemical Resistance: Tyvek is resistant to most acids, bases, and solvents, allowing it to protect components even in harsh environments.

- Durability: With high tensile and tear strength, CleanTech Separators stand up to rigorous handling, ensuring long-term protection without breaking down or shedding fibers.

Advantages Over Other Packaging Solutions

When compared to traditional packaging materials like paper, plastic, or foam, CleanTech Separators offer several key advantages:

- Paper: While paper is prone to tearing and shedding, Tyvek’s continuous fiber structure is much stronger and won’t generate loose particles.

- Plastic: Unlike rigid plastics, Tyvek is lightweight and flexible, conforming to the shape of sensitive components without scratching or causing damage.

- Foam: Foam can break down over time and generate particulates, while Tyvek remains intact, offering better cleanliness and durability.

In industries where contamination and static are critical concerns, Tyvek-based solutions outperform other materials, delivering cleaner and safer results.

Industries Where These Products Are or Could Be Used

CleanTech Separators are utilized across a range of industries:

- Semiconductor Manufacturing: Protects silicon wafers and IC dies during the manufacturing process.

- Electronics Production: Shields components from ESD and contamination during assembly and packaging.

- Aerospace and Defense: Prevents contamination and physical damage to sensitive equipment and components.

- Solar Industry: Safeguards fragile solar cells during production and transport.

Malaster’s Ability for Customization

Malaster offers customization options to meet the specific needs of each application. This includes:

- Size and Shape Configurations: Whether you need small separators for IC dies or larger sheets for protecting wafers, Malaster can tailor the product to fit your exact requirements.

- Custom Packaging Solutions: We can integrate CleanTech Separators into broader protective packaging systems, ensuring every element of your production or shipping process is safeguarded.

Conclusion

CleanTech Separators by Malaster are the ideal choice for industries where cleanliness, ESD protection, and durability are critical. With applications spanning semiconductors, electronics, aerospace, and solar energy, these separators provide the reliability and versatility needed to protect sensitive components from contamination, static discharge, and physical damage.

Malaster’s expertise, combined with our ability to offer customized solutions, ensures that CleanTech Separators meet the stringent demands of today’s high-tech industries. Whether you’re protecting silicon wafers, electronics, or critical aerospace components, CleanTech Separators offer superior protection at every stage.

Explore our CleanTech Separators today and discover why industry leaders trust Malaster for their most sensitive and high-value components.