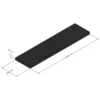

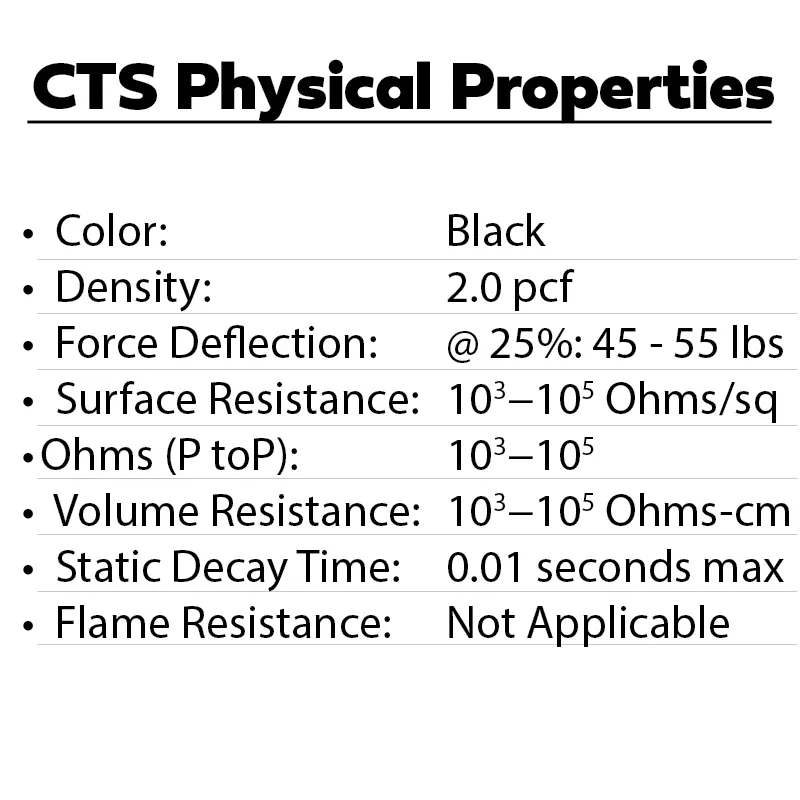

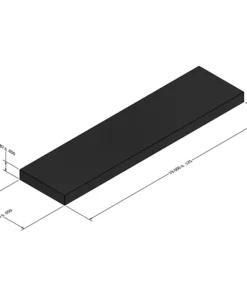

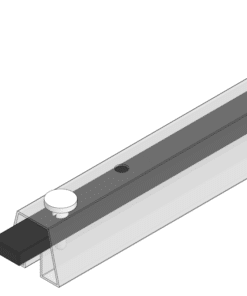

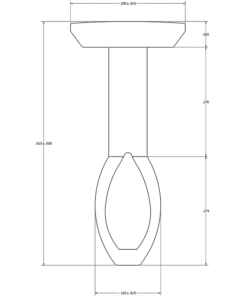

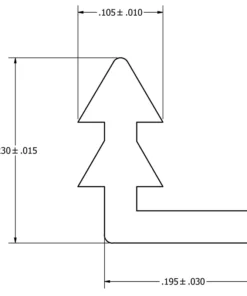

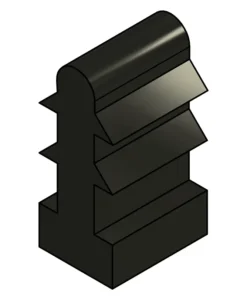

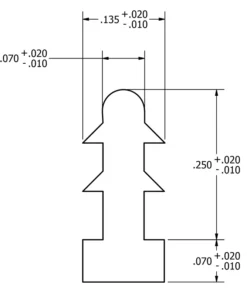

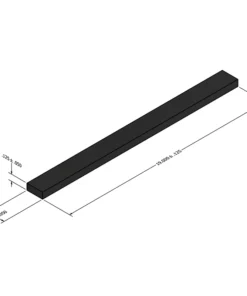

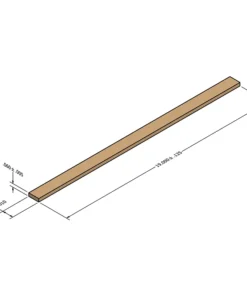

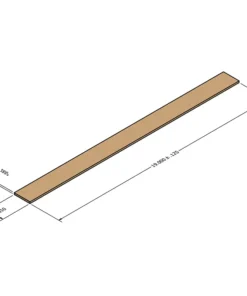

MC-9187CTS : IC Tube Filler

$2.350

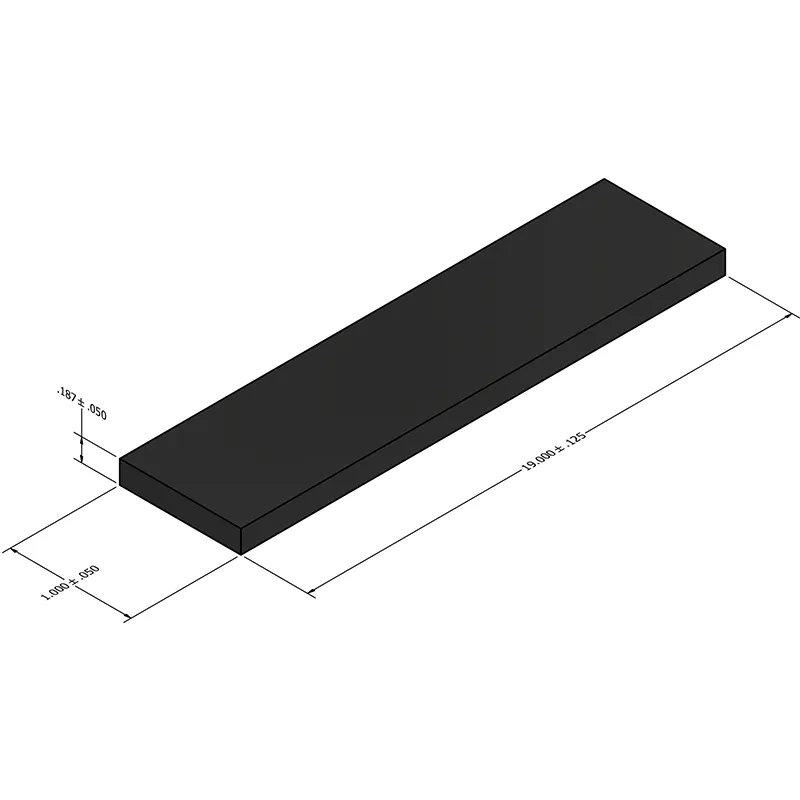

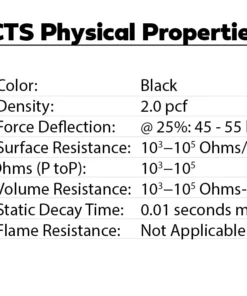

The ESD Tube Filler MC-9187CTS offers reliable static-safe protection for ESD tubes, designed to safeguard components from electrostatic discharge.

| Quantity | Price |

|---|---|

| 0 - 20 | $2.350 |

| 21 - 100 | $1.880 |

| 101 - 250 | $1.410 |

| 251 - 500 | $1.175 |

| 501 - 1000 | $0.940 |

| 1001 + | $0.705 |

Calculate shipping price

Please fill in the fields below with the shipping destination details in order to calculate the shipping cost.

Reviews

There are no reviews yet.