Antistatic Rubber Bands

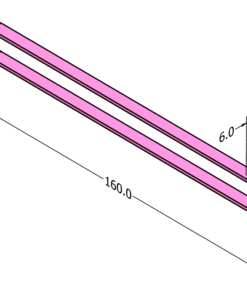

160mm x 6mm (6.25″ x .25″) Antistatic ESD Rubber Band : MC-ASRB1

Antistatic Rubber Bands

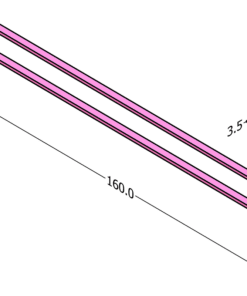

160mm x 3.5mm (6.25″ x .125″) Antistatic ESD Rubber Band : MC-ASRB3

Antistatic Rubber Bands

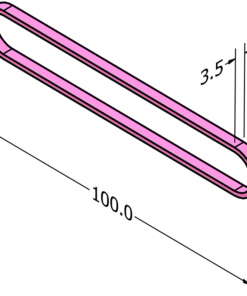

100mm x 3.5mm (4″ x .125″) Antistatic ESD Rubber Band : MC-ASRB4

Antistatic Rubber Bands

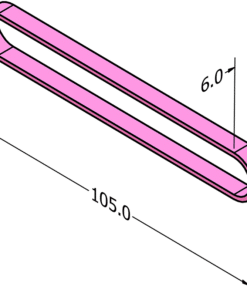

105mm x 6mm (4″ x .25″) Antistatic ESD Rubber Band : MC-ASRB5

Antistatic Rubber Bands

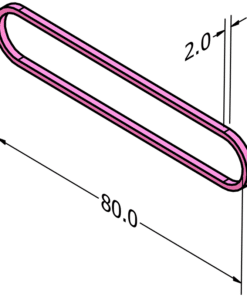

80mm x 2mm (3″ x .062″) Antistatic ESD Rubber Band : MC-ASRB6

Antistatic Rubber Bands

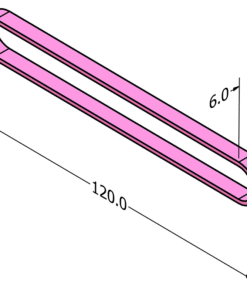

120mm x 6mm (4.75″ x .25″) Antistatic ESD Rubber Band : MC-ASRB7

Antistatic Rubber Bands

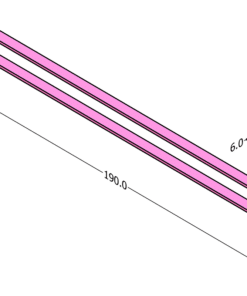

190mm x 6mm (7.50″ x .25″) Antistatic Rubber Band : MC-ASRB8

Antistatic Rubber Bands

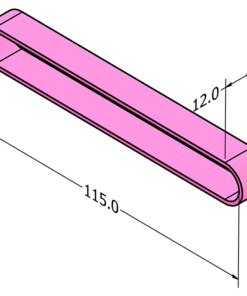

115mm x 12mm (4.5″ x .50″) Antistatic Rubber Band : MC-ASRB10

Antistatic Rubber Bands

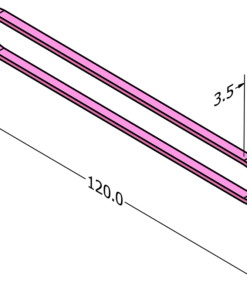

120mm x 3.5mm (4.75″ x .125″) Antistatic ESD Rubber Band : MC-ASRB2

Antistatic Pink Rubber Bands: Reliable Protection for Sensitive Electronics

When it comes to safeguarding sensitive electronic components, Antistatic Pink Rubber Bands are an essential tool in your ESD (Electrostatic Discharge) protection arsenal. These specially designed rubber bands not only provide secure binding and organization of components but also play a critical role in preventing the buildup and discharge of static electricity that can cause irreparable damage to sensitive devices. Whether you’re in electronics manufacturing, assembly, or storage, our Antistatic Pink Rubber Bands offer the perfect balance of elasticity, durability, and antistatic properties.

Why Choose Antistatic Pink Rubber Bands?

Antistatic Pink Rubber Bands are more than just simple fasteners—they are specifically engineered to provide a protective barrier against static electricity. Static discharge is one of the most common and potentially damaging hazards in environments where sensitive electronic components are handled. Here are several reasons why our Antistatic Pink Rubber Bands are the ideal choice for your ESD protection needs:

Comprehensive ESD Protection

Our Antistatic Pink Rubber Bands are designed to dissipate static electricity, reducing the risk of damage to sensitive electronic components. With a surface resistivity ranging from 10^7 to 10^11 Ohms/sq., these bands are perfect for environments where moderate ESD protection is required. The antistatic properties of these rubber bands prevent the accumulation of static charges on their surface, ensuring that your components remain safe from sudden electrostatic discharges that could lead to component failure.

High-Quality Material Composition

The Antistatic Pink Rubber Bands are made from a high-quality blend of natural rubber and antistatic additives. This combination not only provides the necessary elasticity and durability but also ensures that the bands maintain their antistatic properties over time. The use of natural rubber offers superior flexibility and strength, allowing the bands to stretch and secure components without breaking, even under repeated use. The antistatic additives are permanently embedded in the material, providing long-lasting protection against static electricity.

Versatile Size Options

To meet the diverse needs of different applications, our Antistatic Pink Rubber Bands are available in a variety of sizes. Whether you need a small band to secure tiny components or a larger band to bundle multiple items together, we have the right size for you. The available sizes include:

80mm x 2mm (3″ x .062″): Ideal for small components or tight bundling.

100mm x 3.5mm (4″ x .125″): Perfect for medium-sized components.

105mm x 6mm (4″ x .25″): Suitable for securing larger items.

115mm x 12mm (4.5″ x .50″): Best for bundling multiple components together.

120mm x 6mm (4.75″ x .25″): Versatile size for various applications.

160mm x 3.5mm (6.25″ x .125″): Great for long components or bundling cables.

160mm x 6mm (6.25″ x .25″): Ideal for securing bulkier items.

190mm x 6mm (7.50″ x .25″): Perfect for large components or heavy-duty bundling.

These size options ensure that you can find the perfect fit for your specific application, providing a snug and secure hold on your components.

Compliance with Industry Standards

Our Antistatic Pink Rubber Bands are RoHS compliant, meaning they meet the strict guidelines set forth by the Restriction of Hazardous Substances Directive. This ensures that our rubber bands are free from heavy metals and other hazardous materials, making them safe for use in all environments, including those with strict regulatory requirements. Additionally, the bands are manufactured with materials that meet or exceed industry standards for antistatic properties, providing you with peace of mind that your components are protected.

Temperature and Environmental Resistance

The Antistatic Pink Rubber Bands are designed to perform reliably across a wide range of environmental conditions. With a temperature range of -20°C to 70°C (-4°F to 158°F), these bands maintain their elasticity and antistatic properties even in extreme temperatures. Whether your components are stored in cold environments or exposed to higher temperatures during shipping, these rubber bands will continue to provide the necessary protection. Their durability and resistance to environmental factors make them suitable for long-term use in various settings.

Long Shelf Life

One of the critical factors to consider when selecting rubber bands for ESD protection is their shelf life. Our Antistatic Pink Rubber Bands have an estimated shelf life of approximately one year under normal storage conditions. This longevity ensures that the bands will remain effective and reliable over time, providing consistent protection for your electronic components. Proper storage in a cool, dry place will help maintain the bands’ elasticity and antistatic properties throughout their shelf life.

Applications of Antistatic Pink Rubber Bands

The versatility and effectiveness of Antistatic Pink Rubber Bands make them suitable for a wide range of applications across various industries. Here are some of the common uses for these essential ESD protection tools:

Electronics Manufacturing

In electronics manufacturing, components must be protected from static electricity at every stage of production. Antistatic Pink Rubber Bands are used to bundle and secure components, preventing them from coming into contact with one another and reducing the risk of static discharge. Whether used on production lines, in assembly stations, or during the packaging process, these rubber bands play a crucial role in maintaining the integrity of sensitive electronic devices.

Storage and Warehousing

Long-term storage of electronic components requires careful consideration of ESD protection. Antistatic Pink Rubber Bands are an ideal solution for securing components in storage, ensuring they remain free from static buildup. The bands’ ability to maintain their antistatic properties over time makes them a reliable choice for warehousing applications, where components may be stored for extended periods.

Shipping and Logistics

The transportation of electronic components poses significant risks, particularly when it comes to ESD. Antistatic Pink Rubber Bands provide an additional layer of protection during shipping, securing components within their packaging and preventing movement that could lead to static discharge. Their durability and resistance to temperature variations ensure that the bands perform reliably, even under the challenging conditions of shipping and logistics.

Assembly and Workstations

In environments where components are frequently handled, such as assembly lines and workstations, Antistatic Pink Rubber Bands are indispensable. They are used to organize and secure components, reducing the risk of accidental static discharge during handling. The bands’ flexibility allows for easy application and removal, making them a convenient and effective tool for daily use in high-volume assembly operations.

Custom Packaging Solutions

For applications that require customized packaging, Antistatic Pink Rubber Bands can be integrated into tailored solutions to provide optimal ESD protection. Whether used in conjunction with antistatic foam, conductive trays, or other protective materials, these rubber bands can be customized to fit specific product requirements. This adaptability ensures that your components are protected in a way that meets your unique needs.

Optimizing ESD Protection with Antistatic Pink Rubber Bands

When selecting Antistatic Pink Rubber Bands for your ESD protection needs, it’s important to consider how they will be used in conjunction with other protective measures. Here are some tips for optimizing their effectiveness:

Combine with Other ESD Protective Materials

For maximum protection, use Antistatic Pink Rubber Bands alongside other ESD protective materials, such as antistatic bags, foam, and conductive trays. This layered approach provides comprehensive protection against static electricity, ensuring that your components are shielded from every angle.

Proper Storage and Handling

To maintain the effectiveness of Antistatic Pink Rubber Bands, store them in a cool, dry place away from direct sunlight and sources of heat. Proper storage will help preserve the bands’ elasticity and antistatic properties, ensuring they remain reliable throughout their shelf life. Additionally, handling the bands with clean, dry hands will prevent contamination and maintain their performance.

Regular Inspection and Replacement

Regularly inspect Antistatic Pink Rubber Bands for signs of wear, such as cracking or loss of elasticity. While these bands are designed for durability, prolonged use or exposure to harsh conditions can degrade their performance. Replacing worn or damaged bands promptly will ensure that your components continue to receive the necessary protection.

The Importance of ESD Protection in Modern Electronics

As electronic devices become increasingly sophisticated and miniaturized, their susceptibility to ESD damage also increases. The smaller and more complex the components, the more vulnerable they are to the effects of static electricity. Even a tiny discharge can cause significant damage, leading to component failure, reduced performance, or complete device malfunction. In industries where reliability and quality are paramount, investing in effective ESD protection is not just a recommendation—it’s a necessity.

Antistatic Pink Rubber Bands are a simple yet highly effective solution for mitigating the risks associated with electrostatic discharge. By securely bundling and organizing sensitive components, these rubber bands prevent accidental contact and static buildup, which are common causes of ESD-related damage. Their ease of use, combined with their proven effectiveness, makes them an indispensable tool in any environment where electronic components are handled.

Comparing Antistatic Pink Rubber Bands with Other ESD Solutions

While there are various methods and materials available for ESD protection, Antistatic Pink Rubber Bands offer several distinct advantages:

Flexibility and Ease of Use

Unlike rigid ESD solutions such as conductive trays or antistatic bags, Antistatic Pink Rubber Bands provide a flexible and adaptable means of protection. They can be quickly applied and removed, making them ideal for dynamic environments where components need to be frequently accessed, bundled, or re-organized.

Cost-Effectiveness

Antistatic Pink Rubber Bands are a cost-effective solution for ESD protection. Their low price point, combined with their durability and long shelf life, makes them an economical choice for businesses of all sizes. Whether you’re a small electronics workshop or a large-scale manufacturing facility, these rubber bands provide reliable protection without breaking the budget.

Versatility

The versatility of Antistatic Pink Rubber Bands allows them to be used in a wide range of applications, from securing small components to bundling larger items. Their various size options make them suitable for almost any task, ensuring that you can find the perfect band for your specific needs.

Lightweight and Non-Intrusive

Antistatic Pink Rubber Bands are lightweight and non-intrusive, meaning they won’t add significant weight or bulk to your packaging or storage solutions. This makes them particularly useful for applications where space and weight are critical considerations, such as in aerospace and medical electronics.

Environmental Impact and Sustainability

As awareness of environmental issues continues to grow, so too does the demand for sustainable and environmentally friendly products. Our Antistatic Pink Rubber Bands are RoHS compliant, ensuring they are free from hazardous substances such as lead, mercury, and cadmium. This compliance not only makes them safer for use but also contributes to a reduced environmental impact.

Furthermore, the use of natural rubber in the production of these bands supports sustainable practices, as natural rubber is a renewable resource. By choosing Antistatic Pink Rubber Bands, you’re not only protecting your electronic components but also making a conscious choice to support environmentally responsible products.

The Role of Antistatic Pink Rubber Bands in Quality Assurance

In industries where quality assurance is critical, such as aerospace, defense, and medical electronics, the role of Antistatic Pink Rubber Bands cannot be overstated. These industries require stringent measures to ensure that every component meets the highest standards of reliability and performance. Antistatic Pink Rubber Bands contribute to these efforts by providing a simple yet effective means of ESD protection.

By using these rubber bands as part of your overall ESD control program, you can reduce the incidence of ESD-related failures, improve product reliability, and maintain compliance with industry standards. This, in turn, leads to greater customer satisfaction and a stronger reputation for quality.

Conclusion: Invest in Antistatic Pink Rubber Bands for Reliable ESD Protection

In conclusion, Antistatic Pink Rubber Bands offer a comprehensive solution for protecting sensitive electronic components from the risks associated with electrostatic discharge. Their combination of flexibility, durability, and antistatic properties makes them an essential tool for any environment where electronics are handled, stored, or transported.

Whether you’re involved in electronics manufacturing, storage, shipping, or assembly, investing in Antistatic Pink Rubber Bands is a smart choice that will help safeguard your components and ensure their long-term reliability. With a range of sizes available, compliance with industry standards, and a proven track record of effectiveness, these rubber bands are the ideal solution for your ESD protection needs.

Explore our selection of Antistatic Pink Rubber Bands today and experience the peace of mind that comes with knowing your sensitive components are protected by the best in ESD protection technology.