Antistatic Shipping Tubes for QFN / MLF / LPCC

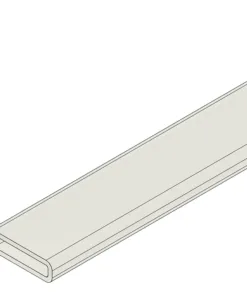

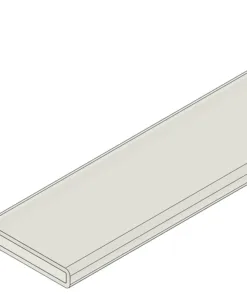

Antistatic Shipping Tubes for QFN (Quad Flat No-lead), MLF (Micro Lead Frame), and LPCC (Leadless Plastic Chip Carrier) devices are specifically engineered to provide reliable and secure packaging for these sensitive components. Crafted from high-quality, ESD-safe materials, these tubes ensure that your electronic devices are fully protected from electrostatic discharge (ESD) and physical damage during handling, storage, and transportation.

The design of Antistatic Shipping Tubes for QFN, MLF, and LPCC packages is optimized to accommodate the unique characteristics of each type of chip carrier. These components are widely used in various electronic applications, such as mobile devices, automotive systems, and high-performance electronics, where compact size and thermal management are critical. Due to their sensitivity to static electricity and physical impacts, proper packaging is crucial to maintaining their functionality and reliability. These tubes provide a snug fit, preventing movement inside, which reduces the risk of damage during transit.

Key Benefits of These Tubes:

- Secure fit: The tubes are designed to hold QFN, MLF, and LPCC devices securely, preventing movement and minimizing the risk of damage.

- Space efficiency: The design minimizes wasted space while ensuring each component remains stable during transport, making them ideal for shipping large quantities of components.

- Stackability and ease of handling: These tubes allow for efficient stacking and secure transportation, simplifying the logistics of handling sensitive electronic components.

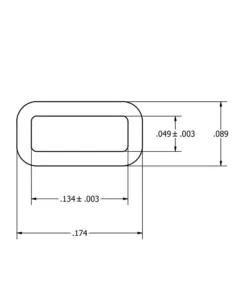

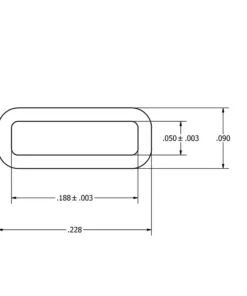

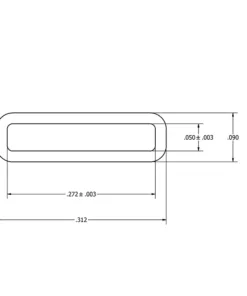

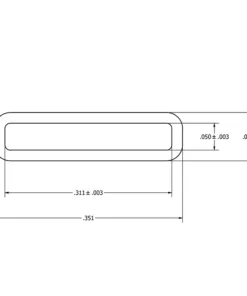

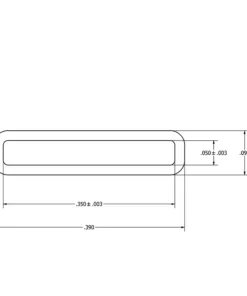

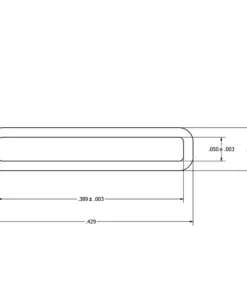

Antistatic Shipping Tubes for QFN, MLF, and LPCC are available in various sizes to accommodate different lead counts, package dimensions, and customer requirements. Whether you’re handling small or large components, there is a tube size to meet your specific needs. Additionally, the tubes come in different colors, such as clear or black, for easy identification and organization.

In manufacturing and distribution environments, these tubes play a vital role in the safe transportation of QFN, MLF, and LPCC devices between different stages of production. From assembly lines to quality control and final shipping, Antistatic Shipping Tubes protect components from both electrostatic damage and physical impact. This level of protection is essential for maintaining product integrity and ensuring components reach end users in perfect working condition.

The antistatic properties of these tubes comply with industry standards for ESD protection, ensuring that your components are handled in accordance with best practices. This compliance helps safeguard your products and assists your business in meeting strict industry requirements.

In summary, Antistatic Shipping Tubes for QFN, MLF, and LPCC offer a reliable and efficient solution for packaging and transporting sensitive electronic components. With ESD-safe materials, secure designs, and multiple size options, these tubes are a critical part of any electronics packaging strategy. Invest in Antistatic Shipping Tubes to ensure your components are fully protected and arrive ready for use.