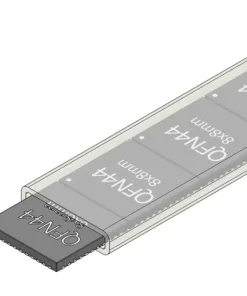

Antistatic Shipping Tubes

Antistatic Shipping Tubes are a critical component in the packaging and transportation of sensitive electronic components, particularly integrated circuits (ICs). These specialized tubes are engineered to protect ICs and other delicate components from the dangers of static discharge and physical damage during handling, storage, and transit. In the world of electronics manufacturing and distribution, maintaining the integrity of these components is paramount, and Antistatic Shipping Tubes play an essential role in achieving this goal.

Detailed Product Specifications

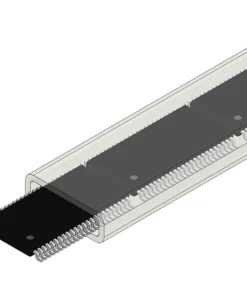

Antistatic Shipping Tubes are typically constructed from materials that are specifically designed to dissipate electrostatic charges. This characteristic is crucial because electrostatic discharge (ESD) can cause immediate or latent damage to electronic components, leading to product failures or reduced performance. The materials used in these tubes often include polyvinyl chloride (PVC), polystyrene, or polyethylene, which are either inherently antistatic or treated with antistatic agents.

These tubes are available in various sizes to accommodate a wide range of component dimensions. Whether you need to package small ICs, larger processors, or other sensitive parts, there’s an Antistatic Shipping Tube designed to fit your needs. Additionally, these tubes are often available in different colors, including clear, black, and other opaque options, depending on the level of protection required and the preferences for visual identification.

The design of Antistatic Shipping Tubes includes features such as end stop pins and plugs, which help to secure the components within the tube, preventing them from shifting during transit. This is particularly important for maintaining the integrity of the components, as even minor movements can lead to physical damage or misalignment of delicate parts.

Practical Applications

Antistatic Shipping Tubes are indispensable in various industries, particularly in electronics manufacturing, distribution, and repair services. The primary application of these tubes is to provide a safe and secure method for transporting ICs from the point of manufacture to assembly lines or distribution centers. Given the fragility and sensitivity of ICs, it’s vital to ensure that they are packaged in a way that minimizes the risk of damage.

In manufacturing environments, Antistatic Shipping Tubes are used to move components between different stages of production. For example, after ICs are fabricated, they may be placed in these tubes for safe transport to assembly areas, where they will be integrated into larger electronic systems. The antistatic properties of the tubes help to prevent ESD events that could compromise the components before they are even installed in final products.

Repair and refurbishment centers also rely heavily on Antistatic Shipping Tubes. When defective or damaged ICs are sent back for repair, they must be transported in a manner that ensures they do not sustain further damage. Antistatic Shipping Tubes provide the protection needed to keep these components safe, allowing repair technicians to focus on restoring functionality without worrying about additional ESD damage.

Moreover, these tubes are widely used in the distribution of electronic components. Distributors and resellers use Antistatic Shipping Tubes to package and ship ICs to customers around the world. In this context, the tubes serve a dual purpose: they protect the components from damage during shipping and handling, and they also help to organize and label parts for easy identification upon arrival.

Key Benefits

The benefits of using Antistatic Shipping Tubes are numerous, making them an essential part of the electronics supply chain. Here are some of the most significant advantages:

- ESD Protection: The primary benefit of Antistatic Shipping Tubes is their ability to protect components from electrostatic discharge. ESD can be devastating to electronic components, causing immediate failure or latent damage that may not become apparent until later stages of use. By dissipating electrostatic charges, these tubes help to prevent such occurrences, ensuring that components arrive in perfect working order.

- Physical Protection: In addition to ESD protection, Antistatic Shipping Tubes provide a sturdy barrier that shields components from physical damage. Whether the threat is from accidental drops, impacts during shipping, or rough handling, these tubes are designed to absorb and deflect forces that could otherwise harm the delicate ICs inside.

- Custom Fit: Antistatic Shipping Tubes are available in a wide range of sizes, allowing for a precise fit for different types of ICs and components. This customization ensures that each component is securely held in place, reducing the risk of movement and associated damage during transit.

- Ease of Use: The design of these tubes, including features like end stop pins and plugs, makes them easy to use. Components can be quickly and securely loaded into the tubes, and the pins or plugs ensure that they stay in place. This ease of use is particularly important in high-volume manufacturing and distribution environments, where efficiency is key.

- Durability: Made from high-quality materials, Antistatic Shipping Tubes are built to last. They can withstand the rigors of shipping and handling, protecting components through multiple stages of the supply chain. This durability also means that the tubes can often be reused, providing additional cost savings for businesses.

- Organizational Benefits: The ability to choose different colors and label Antistatic Shipping Tubes allows for easy identification and organization of components. This is particularly beneficial in environments where many different types of ICs are handled, as it simplifies the process of locating and selecting the correct parts.

- Compliance with Industry Standards: Many Antistatic Shipping Tubes are designed to meet or exceed industry standards for ESD protection and packaging. This compliance ensures that businesses using these tubes are adhering to best practices for component protection, reducing the risk of damage and liability.

Customization and Conclusion

In addition to the standard options available, Antistatic Shipping Tubes can often be customized to meet specific needs. For example, some manufacturers offer the ability to produce tubes in custom sizes or with specific antistatic properties tailored to unique applications. This customization ensures that even the most specialized components can be protected during transit.

When selecting Antistatic Shipping Tubes, it’s important to consider the specific requirements of the components being shipped. Factors such as the size and sensitivity of the ICs, the expected conditions during transit, and the handling practices in place should all be taken into account. By choosing the right tubes, businesses can significantly reduce the risk of component damage, ensuring that their products reach customers in perfect condition.

In conclusion, Antistatic Shipping Tubes are a vital part of the electronics supply chain, providing essential protection for integrated circuits and other sensitive components. Their ability to prevent electrostatic discharge and physical damage makes them indispensable in manufacturing, distribution, and repair environments. With a wide range of sizes, materials, and customization options available, Antistatic Shipping Tubes offer a reliable and effective solution for safeguarding valuable electronic components during transit.

Explore our comprehensive selection of Antistatic Shipping Tubes to find the perfect solution for your packaging needs. Whether you’re looking to protect small ICs or larger components, our tubes offer the durability, protection, and ease of use that your business requires. Invest in Antistatic Shipping Tubes today to ensure the safety and reliability of your electronic components from manufacture to final delivery.